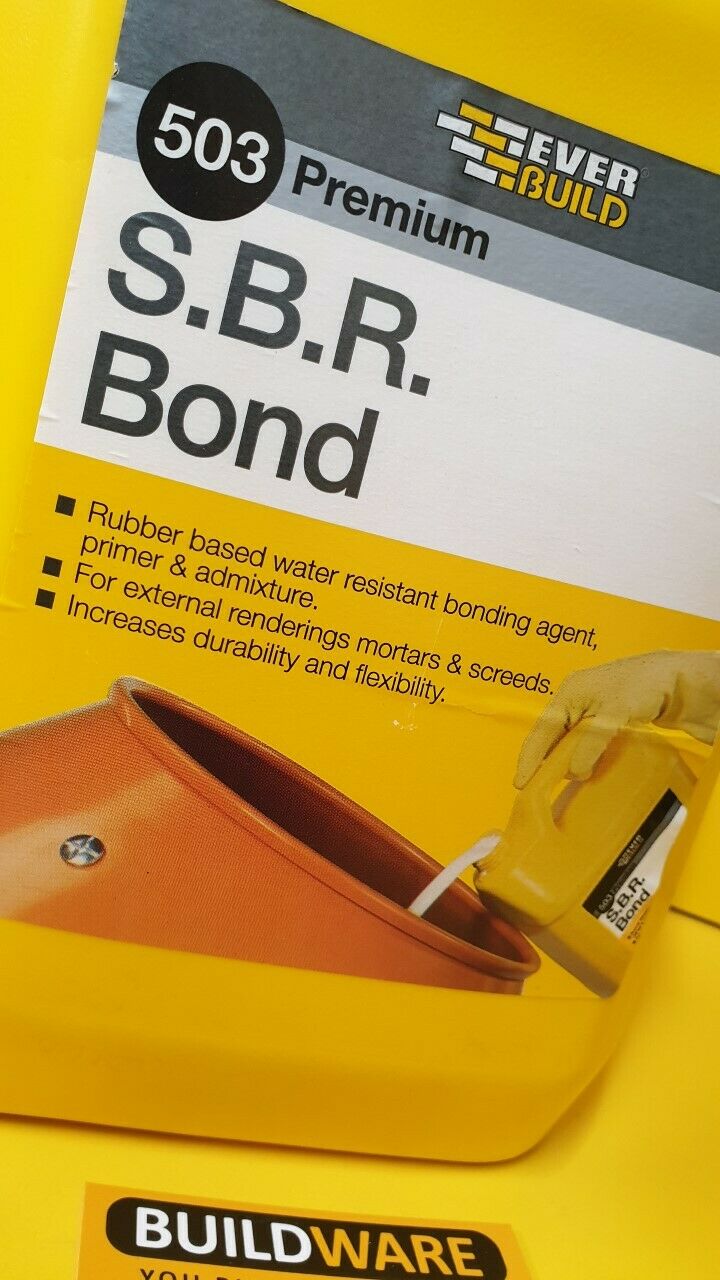

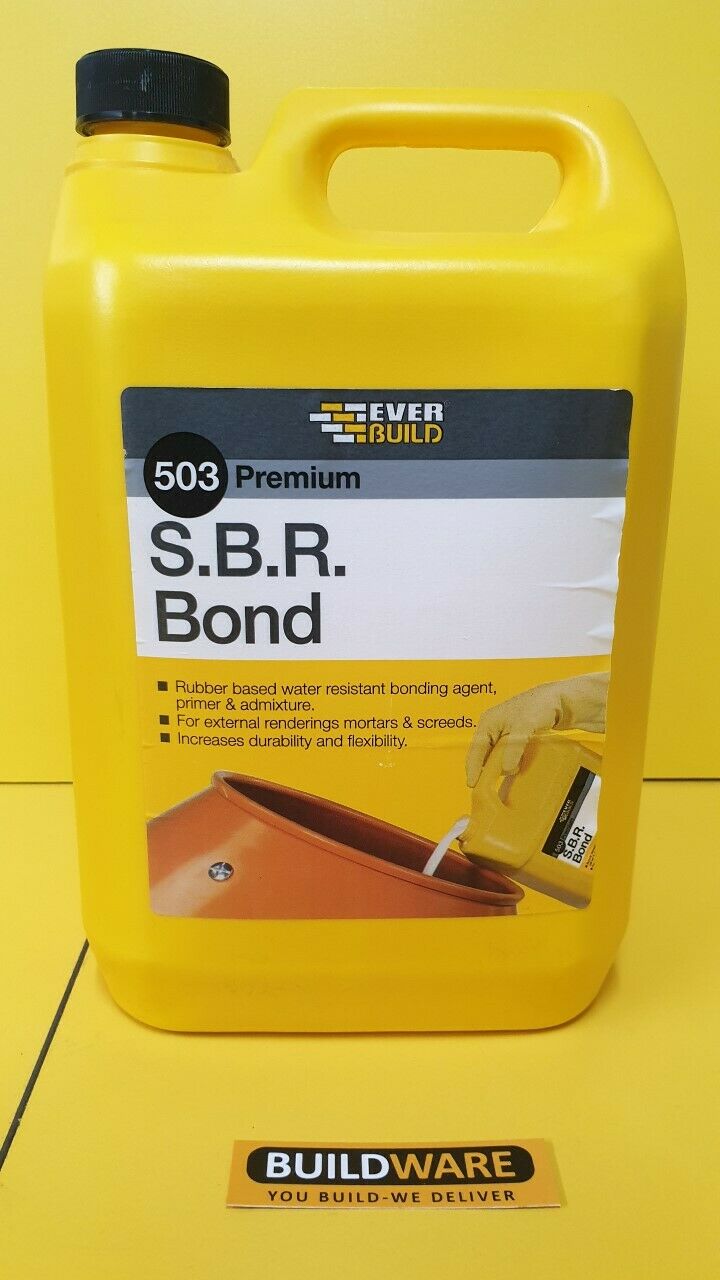

Everbuild 503 SBR bond

£27.99

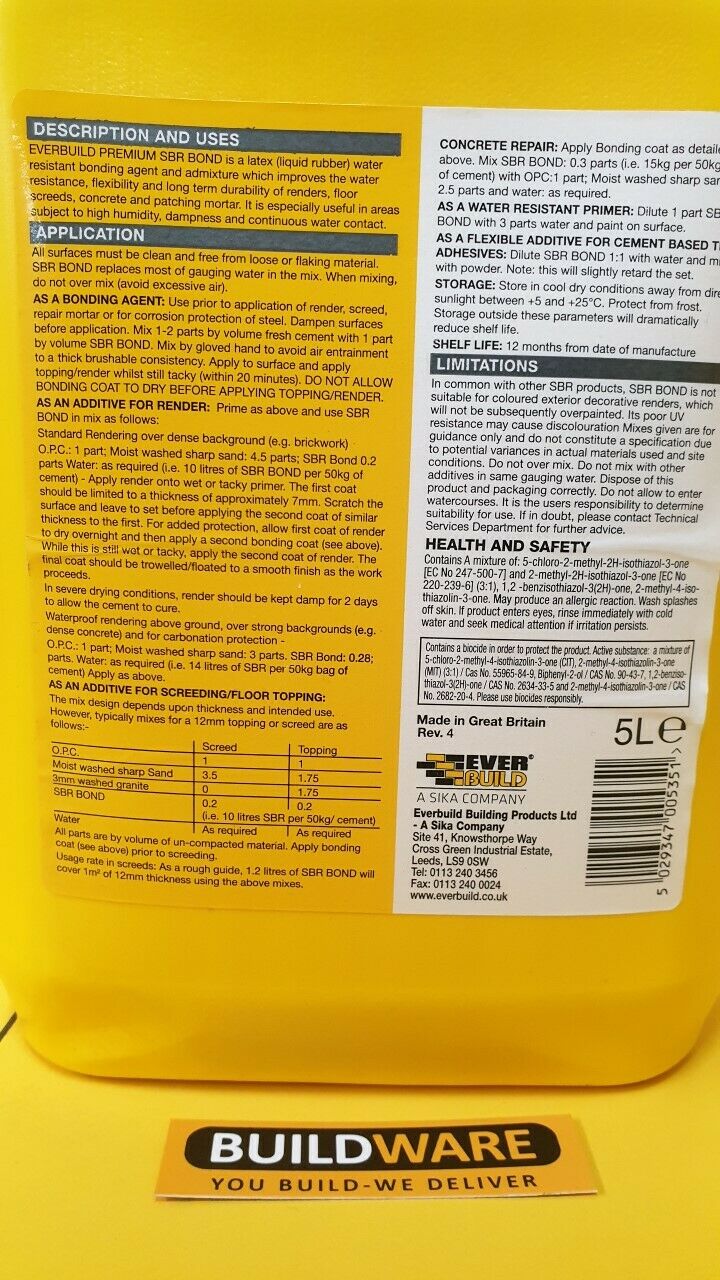

Uses: as an admixture for mortar/screeds/renders. As a bonding agent for screeds/renders. As a primer/sealer in tiling applications. To increase flexibility for cementitious-based tile adhesive when tiling on wooden/asphalt floors. In addition, sbr bond has the advantage over pva bonding aids in that it is not adversely affected in wet conditions and is therefore recommended for exterior use. Features: greatly improved adhesion to a wide range of substrates including dense concrete, steel, tiles etc. Mixes may be applied in much thinner sections excellent resistance to water and water vapour a high level of resistance to salt permeation much-improved toughness and flexibility reduced surface dusting of concrete greatly improved resistance to many chemicals reduced water: cement ratio for equivalent workability improved frost resistance sbr bond is also freeze-thaw stable storage conditions: everbuild 503 premium sbr bond is best stored at 5 to 25 ºc. However if frozen, the latex should be thawed slowly. Everbuild 503 premium sbr bond should preferably be stirred before use. Application instructions:- substrate preparation -all surfaces must be clean, dry and free from dust, grease, and other contaminants. The background must be capable of withstanding all stresses which will be put onto it and contain the appropriate joints. If it is to receive a topping the background should have a compressive strength greater than 30n/mm² and/or a tensile strength greater than 1n/mm². Floors should be mechanically prepared, eg scabbled or shot blasted, to give an aggregate exposed surface. Dust should be removed by vacuum, not compressed air. All contaminants such as oil, grease, or any surface laitance must be removed to ensure adequate development of bond when the topping is applied. A water drop test is the simplest method to determine whether water repellent contamination is present.- mixing -mixing procedures for topping and screeds containing ever build 503 premium sbr bond are similar to those used to conventional compositions, with gauging water partly replaced by ever build 503 premium sbr bond. However, mixing time should be minimized to limit air entrainment. Mixing should be carried out in a forced action mixer. The usual procedure is to pre-mix sand and cement in the mixer, pour in the everbuild 503 premium sbr bond, mix for 1 – 3 mins, then slowly add water to the required consistency.- priming -application of a primer coat is necessary to obtain maximum adhesion of the topping or screed.- sbr bond flooring applications -this concerns the use of everbuild 503 premium sbr bond in screeds and toppings over background concrete. Adding everbuild 503 premium sbr bond to a floor screed or topping gives the following advantages: low water: cement ratio allows a minimum of delay when overcoating is required. Reduced permeability to liquids.Improved chemical, abrasion, and impact resistance. Resistance to dusting. Thinner screeds, achieving a reduction in weight and savings in materials. Excellent slip resistance. Goods underlay for epoxy surfacing. Everbuild 503 premium sbr bond has a long and successful track record of use in the construction industry.- selection of materials -to obtain maximum performance from mixes modified with everbuild 503 premium sbr bond it is important that attention is paid to the quality of the other materials used. Sand should be well washed and sharp. The grade of sand will depend upon the mix design. Cement portland, high alumina and sulphate resisting cement are compatible with sbr bond. Portland cement should be fresh but cool. Cement containing air set lumps should not be used. Coarse aggregate e.G. Granite chippings. These should be dust-free. Air entraining agents should not be used.- pot life -the mix has a pot life of approximately 30 minutes and batch size should be calculated accordingly.- application -apply topping or screed onto the wet or tacky primer. Compact and level with screed bar. Finish with a steel float. It is essential that the topping or screed is finished as the work proceeds. The topping or screed would be cured for 1 – 2 days using conventional techniques. Curing should be started quickly after application.

- Everbuild – 503 sbr bond 5l – water resistant latex bonding agent admix s.B.R:

- Sbr bond is a latex-based, water-resistant bonding agent and admixture for use in areas subject to humidity, dampness, and continuous water contact.

- It improves the water resistance of cement mixtures by forming a reinforcing polymer that increases the long-term durability and flexibility of the mix on renderings and floor screeds.

1 in stock

Share

Description

- Everbuild – 503 sbr bond 5l – water resistant latex bonding agent admix s.B.R:

- Sbr bond is a latex-based, water-resistant bonding agent and admixture for use in areas subject to humidity, dampness, and continuous water contact.

- It improves the water resistance of cement mixtures by forming a reinforcing polymer that increases the long-term durability and flexibility of the mix on renderings and floor screeds.

Additional information

| Brand |

|---|

Reviews (0)

Be the first to review “Everbuild 503 SBR bond” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.